Purpose of waste oil distillation and regeneration equipment:

Waste oil distillation and regeneration base oil equipment mainly purifies and regenerates waste oil by distillation. According to different pollution sources and impurity characteristics of waste oil, it can effectively remove debris, asphaltene, wax, impurities, water, acid, organic acid and inorganic acid in waste oil. In the waste oil, oil deterioration is only part of the hydrocarbons, and most of the other hydrocarbons are still the main viscosity carrier of lubricating oil. As long as the deterioration and impurities are removed, the waste oil can be regenerated into the base oil with the required quality, and then various additives can be added as needed to produce the required product oil. The main waste oils are waste engine oil, waste hydraulic oil, waste gear oil, waste black oil, waste quenching oil, waste heavy oil, waste diesel oil, waste lubricating oil, waste tire oil, waste plastic oil, waste cutting oil, etc. Waste oil regenerative distillation equipment belongs to energy-saving and environmental protection products. In the process of treatment, the waste gas is treated by a special waste gas recovery system without air pollution. The treated sludge residue can be reused as fuel.

Introduction of Waste Oil Distillation Process

1.Transfer the waste oil to the distillation kettle, start the heating system, start the stirring device in the distillation kettle at the same time, increase the heat transfer speed of the waste oil, so that the waste oil can be uniformly heated in the distillation kettle. Because there are many impurities in the waste oil, such as colloid, asphalt and free carbon, stirring the waste oil can effectively prevent these substances from coking, thus blocking the distillation device and pipeline.

2.The waste oil is gradually heated in the distillation reactor. When the temperature reaches 55 C, the gasoline component in the waste oil will be distilled gradually. The distilled gasoline will be cooled by water and gasoline condenser to obtain extensive gasoline oil. When the temperature of waste oil reaches 100 - 220 C, the water in waste oil begins to be distilled. The distilled water vapor is cooled by water and gasoline condenser, and the cooling water and gasoline will enter the water and gasoline collector. Because the densities of water and gasoline are very different, they will automatically stratify, drain the water from the collector, and then filter the gasoline to get the finished gasoline.

3.When the temperature reaches 160 C, close the valve of the gasoline production line and switch to the diesel production line.

4.As the temperature of waste oil increases gradually, the light components in waste oil are distilled gradually. Then these components are further catalyzed by high-efficiency catalytic device. Then the oil vapor composed of diesel oil is obtained. After the oil vapor is cooled by the diesel condenser, the diesel oil is obtained.

5.When the temperature of waste oil reaches 260 C, the heavier components in waste oil are distilled. The heavier components will be catalytically cracked by the high-efficiency catalytic device. After the catalytic cracking, the oil and gas will enter the catalytic conversion device. A certain amount of additives will be added to the entrance of the additives of the catalytic conversion device, and then the oil and gas after the additives are added will be catalyzed. The output pump re-enters the high efficiency catalytic cracking unit for further catalytic cracking. In this way, we can get high quality diesel oil vapor, which will be cooled by diesel condenser to get liquid diesel.

6.Finally, we filter all the diesel oil to get the finished diesel oil.

7.When the temperature of the distillation kettle reaches about 410 C, start the residue pump and pump the residue out of the distillation kettle. That is to say, the residue obtained can be used as heavy fuel oil.

8.The non-condensable gases produced by distillation, catalysis and pyrolysis of waste oil are treated with tail gas. The treated tail gas meets the emission standard and is discharged.

Advantages of waste oil distillation and regeneration equipment:

1.The equipment belongs to the project of environmental protection, energy saving and waste oil regeneration, and it is a project benefiting mankind.

2.Vacuum vacuum distillation has low distillation temperature and high working vacuum.

3.A new type of distillation tower with three-dimensional recirculating tower is adopted, which has high distillation efficiency and low energy consumption.

4.The main parts of the equipment are made of stainless steel with long service life.

5.No chemical additives are added in the distillation process of equipment treatment. The operation cost is low and pollution-free.

6.Combining oil-cooling system with water-cooling system, the cooling efficiency is high.

7.The system design is reasonable, the operation is simple and the maintenance is convenient. The treated residues can be used as fuel or other uses.

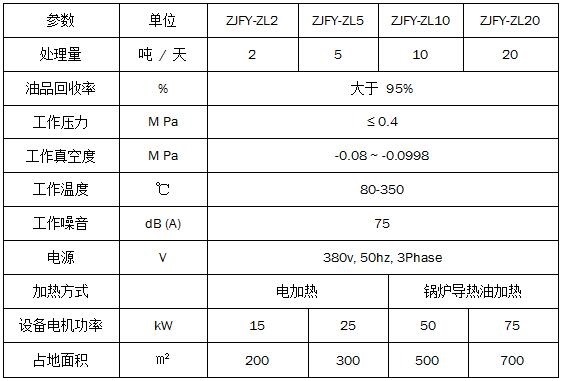

Waste oil distillation and regeneration equipment parameters: